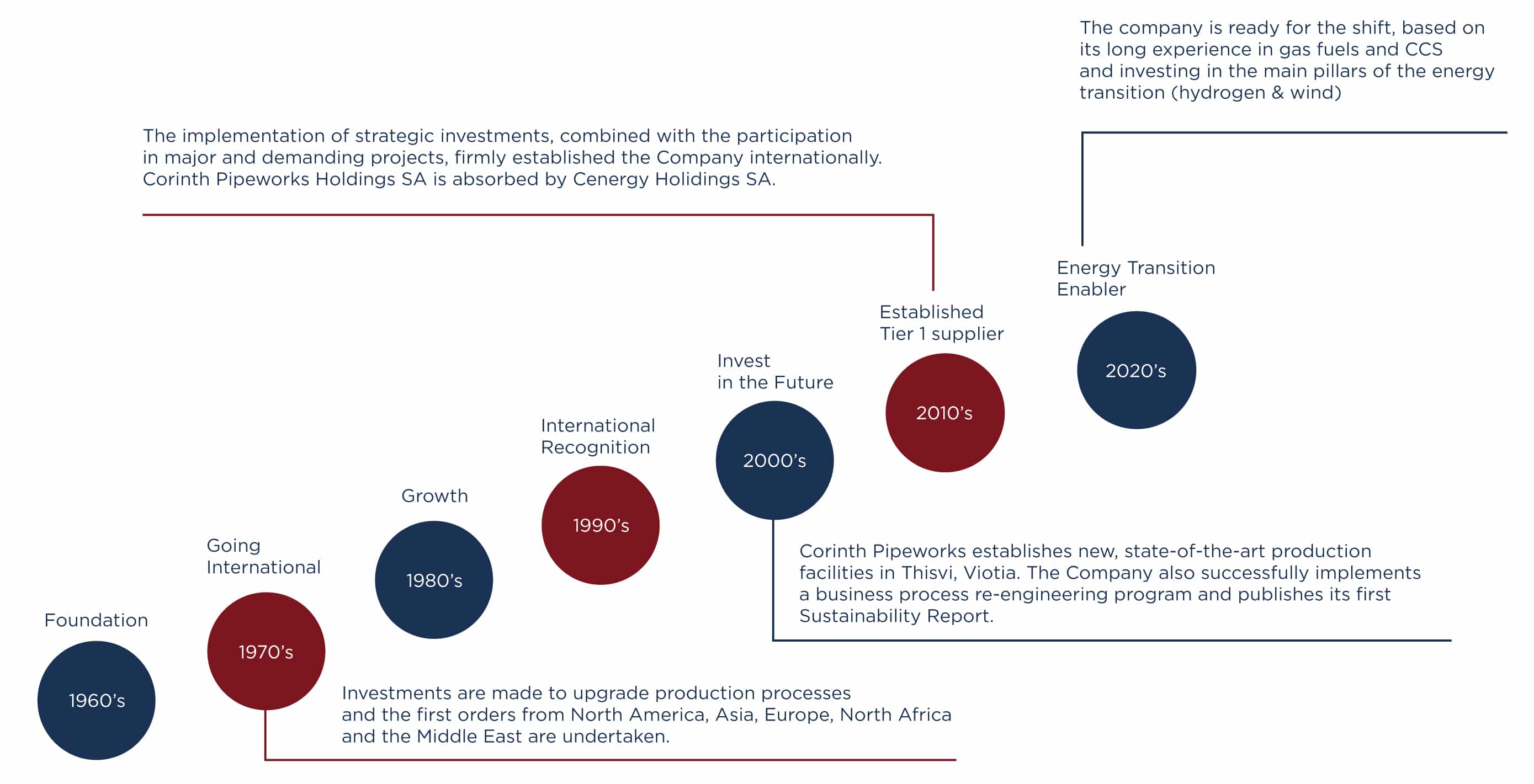

Natural gas is often considered as the transitional fuel to a clean energy future, producing around half the carbon dioxide (CO2) and just one tenth of the air pollutants of coal when burnt to generate electricity. Natural gas is an ideal, cost-effective partner to renewable energy sources, such as wind, solar, hydrogen and hydropower, providing a consistent back-up source of power to their variability.

For several years now, Corinth Pipeworks, focuses on gas transmission projects at a rate of more than 90% of its activity in the energy sector.

At the forefront of technological innovation, our research and development in the field of hydrogen transportation, through existing or new energy networks, developing technology and new products will enable the clean transformation to a coal-free, clean energy economy. As a result, Corinth Pipeworks along with International energy infrastructure companies is leading the hydrogen era with the first high pressure gas pipeline network, certified to transport up to 100% hydrogen.

Now we are going one step further by expanding our capabilities with of our accredited testing center: a new state-of-the-art hydrogen testing laboratory. This laboratory is among the first of its kind for a pipe manufacturer worldwide, offering capabilities to address the need of the energy market for the development of a hydrogen network to achieve climate and energy objectives.

To this direction, we are one of the leading manufacturers of steel pipes for the energy sector and the first, globally, to participate in the European Alliance for Pure Hydrogen (Hydrogen Alliance) as well as in Hydrogen Europe. Our experts participate in the Technical Committees and Working groups with the view to find solutions in a cost effective way to the secure transportation of hydrogen and also contribute to the important task of Standardization & and Regulations

Corinth Pipeworks offers a wide range of products for the construction sector, serving the steel construction market with its extensive range of Structural Pipes and Hollow Structural Sections in Square, Rectangular and Round shapes, used in Architectural, Industrial and Infrastructure applications. Material know-how and manufacturing expertise, in addition to knowledge of markets and applications, establish our companies ready to develop individual solutions to strengthen the customer’s position in their specific market.

For the last 15 years the Company has produced CO2 transmission pipelines with a total length of over 1,150 km and is ready to face any new challenge in the immediate production of products that will allow the application of this technology on a large scale.

Today, wind energy offers a technologically mature, economically competitive and environmentally friendly energy choice. It is an inexhaustible source of energy, without an environmental burden. The wind energy sector is one of the fastest growing energy technologies, especially in offshore wind parks and dynamically in floating wind parks. Steel products are broadly used in these dynamically developing sectors fit our competencies and are under study, fully in line with the company’s diversification strategy.